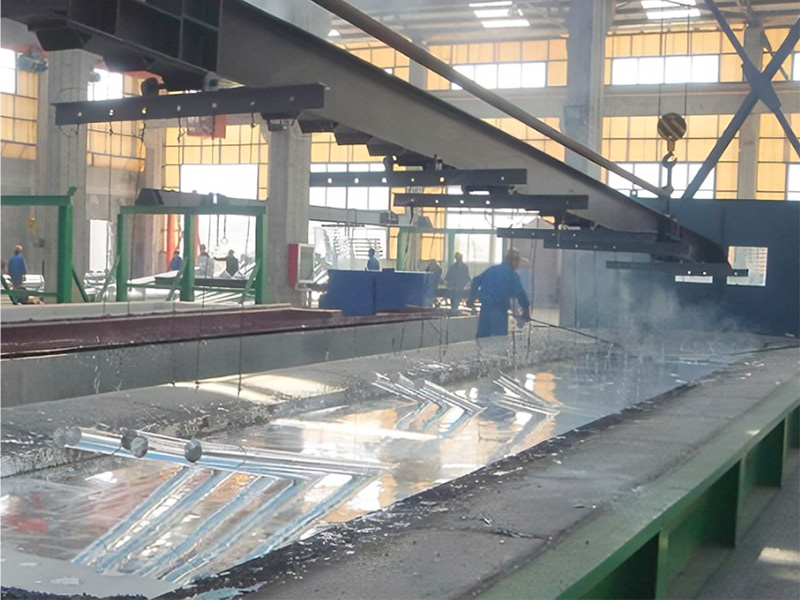

Our pole can be used - hot-dip galvanized to achieve surface protection for pole.

Highly resistant to corrosion, hot-dip galvanizing is highly resistant to corrosion in most environments. By forming a strong zinc-iron alloy coating on the steel surface, it effectively resists corrosive substances in the atmosphere, water and soil.

The coating is uniform and dense. After hot-dip galvanizing, the coating formed is uniform and dense, completely covering the steel surface. This uniform coating can provide long-term protection and can resist the erosion of various external corrosive factors.

Controllable Coating Thickness

According to different application requirements, the coating thickness of hot-dip galvanizing can be controlled. Usually, the thickness of the coating can reach 50 to 100 microns, which can be adjusted according to specific conditions to meet the requirements of different application scenarios.

Strong Coating Adhesion

After hot-dip galvanizing, a solid chemical bond is formed between the coating and the steel substrate, which has strong adhesion. Even in harsh environments, such as vibration, shock and other conditions, it can maintain the stability of the coating.

Hot-dip galvanizing is also easy to maintain. If it needs to be repaired or replaced, simply apply a new zinc coating.